To maintain seam quality and operating efficiency, the following steps are essential:

Preventative maintenance should be performed regularly and seaming machines maintained to the manufacturer’s specifications. Machine setup audits should be done regularly and machine adjusted as needed.

Clean and lubricate your seamer as recommended by the manufacturer.

Set up the seamer in a disciplined manner as recommended by the manufacturer for the type of can to be seamed.

Evaluate double seams regularly to confirm the seamer is producing the required double seam quality, both after setup and under production conditions.

Keep detailed records of all results obtained and actions taken.

Establish statistical methods to evaluate double seam quality. Center seam components to nominal dimensions and evaluate data for excessive variation.

Know when to make the correct adjustment at the appropriate time.

Double Seam Inspection Tools

Can Seam Micrometer for manual measurement of width, height, and depth of can seams.

The SeamMate System is a convenient and accurate way to inspect double seams.

Manual Seam Saw for making cuts across the double seam for measurement.

Flange Width Gauge

Hand Held Countersink Gauge

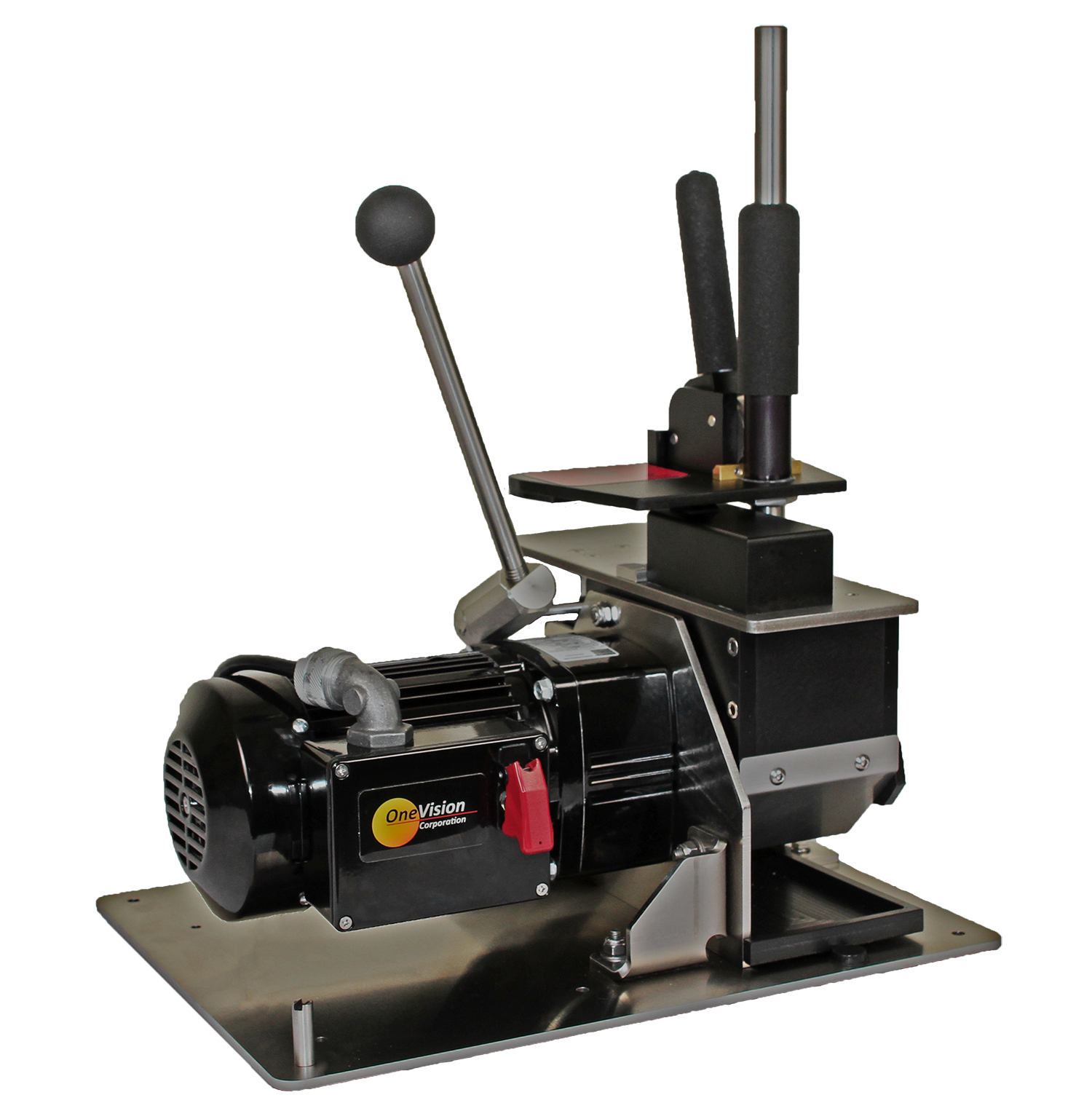

The Automatic Seam Saw is a safer and quieter option for cutting across the double seam for measurement.

The Double Seam Stripper is a quick and safe way to remove the cover hook for tightness inspection and measurement.

The Mini Seam Stripper is a compact seam stripper ideal for beverage canners.